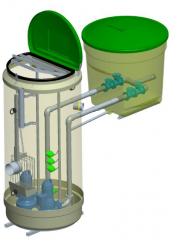

A Maxylift lifting or discharge station allows for the collection of wastewater and/or stormwater in all cases where effluents arrive lower than the point where they are to be discharged. The Maxylift is a prefabricated factory assembly designed to simplify the installer's job. The shell is made of glass reinforced polyester (PRV) by cross filamentary winding, ensuring an excellent mechanical resistance and an anti-corrosion guarantee (in particular against H2S which attacks materials such as concrete).

Special features of the Maxylift range in GRP:

Tanks Ø1000,1300,1600,1900 or 2300.

Standard heights from 1.5 m to 6 m and more on request.

Factory pre-equipped stations (internal piping / fittings / guide bars) to receive the pumps directly on site during commissioning.

Custom-made control cabinets.

Options on demand