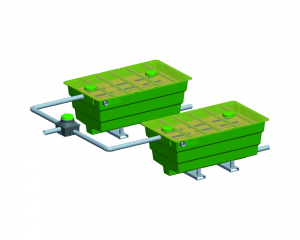

6055

ZEOMOP without pumping station

(Also refer to standard XP P16-603) The 2-tank system will be buried outside a building in a zone protected from vehicles passing through it or parking there. 2 straps (ref AD055C) will be delivered in a separate package to be used for the handling and burial of tanks on site. Installation on dry ground: The area is to be carefully terraced and then a 10 cm thick bearing bed will be created for the Zeomop tanks using perfectly leveled and compacted sand (a 200 kg / m3 sand stabilized with cement can be used). The pipes and aeration system are connected and the purification platform level is to be checked before lateral backfilling with sand to cover the top of the assembly. The covers should be level with the finished ground (use cast iron covers Ref RH2/03/15). Installation on damp ground or hydromorphous soils: If necessary, carry out drawdown of the surface during installation of the system. The area is to be carefully terraced and then a 10 cm thick perfectly level invert in liquid armoured concrete will be created to allow installation of the Zeomop tanks before the concrete hardens (leave the retainer rings around the invert). The pipes and aeration system are connected and the purification platform level is to be checked before a layer of liquid concrete is poured to cover the feet of the Zeomop tanks. Continue lateral backfilling with sand to cover the top of the assembly. The covers should be level with the finished ground (use cast iron covers Ref RH2/03/15). The ZEOMOP must not be buried at a depth of over 75 cm between the top of the tank to the finished ground. BEWARE! Do not pour a concrete slab over the top of the Zeomop as the top of each Zeomop tank must remain accessible. Depending on the terrain’s topography, install one Simop pumping trap adapted to the type of effluent and the tank volume validated by our Design office following tests carried out to optimize the purification yield of the device. Three installation configurations are possible for the pumping trap: 1/ Simplimop wastewater pumping station upstream from the all-water tank. 2/ Viagrimop clean water pumping station between the all-water tank and the water spreader manhole in front of the zeolite filter. 3/ Viagrimop clean water pumping station downstream from the zeolite filter tanks for disposal in the soil environment. For configurations 1 and 2, the pumping station must be connected with a PVC 40/100 augmentation in an inspection chamber in order to ensure gravitational flow to either the tank or the zeolite media filter.

Tanks made from GRP are anti-corrosive and do not therefore require any maintenance in particular. The spreader system should be cleaned with a high pressure water jet once a year via the inspection apertures designed for this use. The drainage device should also be cleaned via the manhole Ø 100 concentric tube. Check that the aeration pipes are not blocked.

Each unit of the ZEOMOP system is equipped with two apertures of Ø100 for aeration. These must be respectively connected to an inlet (primary aeration on the upper inlet) and an air extraction fan (secondary aeration via passive extraction or a wind pump which can be that of the all-water tank). Each unit can be independently ventilated from the other or they can be connected in tandem).