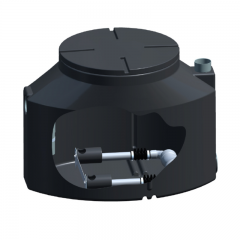

Equipment of pre-treated domestic sewage networks allowing the sequential feeding of a purification unit.

6378

Fleating buckets

The device should be buried as close as possible to the pre-treatment unit.

The bottom of the excavation must be perfectly flat and covered with at least 10 cm of sand.

The embankment will be done with washed sand and in no case with stone, gravel or soil.

Before backfilling, fill the tank with clean water up to the maximum level before filling the float.

In case of passage of vehicles within a radius of 3 meters, the device must receive on the periphery a concrete slab resting on the undisturbed ground. This slab will be calculated to withstand the constraints imposed without reliance on the device.

The cover must always remain accessible for maintenance. In case of presence of ground water or flood plain, consult our Design Office.

LOCATION

Downstream of a primary treatment unit type all-water pit or decanter-digester.

OPTION:

- Tarpaulin counter

ADVANTAGES

- Works without external energy.

- Allows a homogeneous feed by tarpaulins from the spreading network or the filtration unit.

- Avoids clogging of the distribution network.

- Distributes the effluent evenly over the filter bed to optimize its operation.

- Optimizes the treatment efficiency of the treatment sector.

MANUFACTURING

- Polyethylene tank with screw cap.

- floating bag made of polyethylene. Additional equipment in stainless steel ref: 304 L.

- Polyurethane hose between floating bucket and evacuation.

OPERATION

- At rest, the float is in horizontal position in the bottom of the tank.

- When the wastewater arrives, the float rises to the maximum level defined by the stop. The float fills with water and flows to the bottom of the tank. This action causes the flushing of the effluents.

- Clean the float and the bottom of the tank annually.

- Check the condition of the hose which is a wear part.