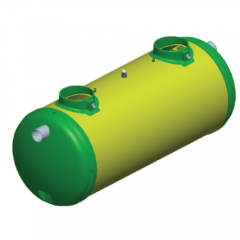

A grease separator is an apparatus for the retention of solids, greases and oils contained in domestic wastewater. The dimensioning of our separators is in conformity with the European standard NF EN 1825-1.

In the case of small communities and professional facilities (central kitchens, canteens, restaurants, hotels, butchers, deli meats, caterers, cured meats, etc.), the obligation to install fat separators results from the standard departmental health regulations public health code.

This manual is devoted to polycomposite devices from 25 to 100 l / s.

Hydraulic characteristics selected in accordance with standards

- Area: 0,25 m² per l / s

- Sludge capacity: 100 l per l / s minimum

- Separator capacity: 240 l per l / s minimum

- Yield: 92%

- Grease retention capacity: 40 l per l / s

Physical characteristics :

- Polycomposite tank reinforced with fiberglass

- 2 holes of men

- PVC inlet and outlet

An aid to the study of the design will be made by our technicians after receiving the elements requested on our study document Q203.