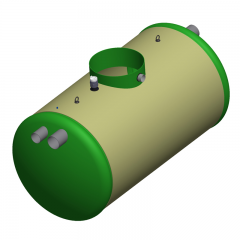

A combined fat and starch separator is an apparatus for separating and storing solids, fats and oils of animal and plant origin contained in greywater and for retaining peeling debris.

A starch foam spraying system is installed above the arrival of effluents from the potato peeler.

The control of the spray system must be controlled by the peeler.

The device, as standard, is equipped with a manhole primer of Ø 750, optional, the device can be equipped with a collar and a screw cap Ø 600 (OD3 / CV600 / ... ). On this cover can be mounted extensions to screw height 250mm (option RH602).

A V100 sludge zone is integrated in each device.

Our devices comply with the NF EN 1825-1 standard and are CE marked.

The grease retention capacity is 40 liters per l/s