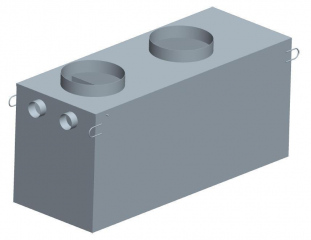

A combined fat and starch separator is an apparatus for separating and storing solids, fats and oils of animal and vegetable origin contained in greywater and for retaining peeling debris.

A starch foam spraying system is installed above the arrival of effluents from the potato peeler. The control of the spray system must be controlled by the peeler.

A V100 sludge zone is integrated in each device.

The fat retention capacity is 40 liters per l / s.

Manufactured in 304 L stainless steel (EN 1.4307).

Equipped as standard with a grease level sensor holder.

Buried implantation, with possibility of manufacturing on site (contact us).

Chimney primer (diameter 600, height 120mm).

Without cover (s), the extension system (s) and the cover (s) according to EN 124 are not supplied SIMOP.