Service stations, also known as fuel stations, refueling areas or fuel distribution points, must comply with strict environmental protection standards, particularly when it comes to treating run-off water. An essential piece of equipment for any service station is the hydrocarbon separator.

What is a hydrocarbon separator?

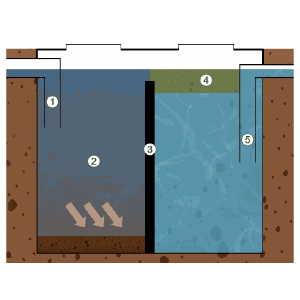

A hydrocarbon separator is a device designed to remove hydrocarbons (gasoline, diesel, oils) from run-off water. This water can come from rainfall running over station surfaces, vehicle washing or accidental fuel spills. By preventing these pollutants from entering the sewage system or groundwater, the hydrocarbon separator plays a crucial role in protecting the environment.

Why install a hydrocarbon separator at a service station?

- Regulatory compliance: Service stations are subject to strict regulations governing the treatment of run-off water. In most countries, regulations require the installation of hydrocarbon separators for all fuel storage and distribution facilities.

- Environmental protection: Hydrocarbons are major pollutants that can cause serious damage to flora and fauna. Installing a hydrocarbon separator helps reduce the environmental impact of service station activities.

What criteria should you take into account when choosing a hydrocarbon separator?

- Treatment capacity: The separator’s capacity must be adapted to the volume of runoff water from the service station.

Standards and certifications: Make sure the separator you choose meets local standards and has the necessary certifications. - Maintenance: Opt for a separator that is easy to maintain, to ensure its smooth operation over the long term.

Find below the SIMOP range of hydrocarbon separators for service stations:

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 sludge trap, top: circular primers 7 [4730] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 sludge trap, top: circular primers - Main image](https://simop.com/wp-content/uploads/2024/11/4730-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-v100-sludge-trap-top-circular-primers-main-image-800x800-optimized.png)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 silt storage, top: unenclosed 8 [4731] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 silt storage, top: unenclosed - Main image](https://simop.com/wp-content/uploads/2024/11/4731-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-v100-silt-storage-top-unenclosed-main-image-800x549-optimized.jpeg)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: circular primers 9 [4732] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: circular primers - Main image](https://simop.com/wp-content/uploads/2024/11/4732-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-with-bypass-v100-sludge-trap-top-circular-primers-main-image-800x800-optimized.png)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: without closure 10 [4733] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: without closure - Main image](https://simop.com/wp-content/uploads/2024/11/4733-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-with-bypass-v100-sludge-trap-top-without-closure-main-image-800x800-optimized.png)

![CE steel hydrocarbon separators 5 mg/L, 1.5 to 50L/s, V100 sludge trap 11 [4798] CE steel hydrocarbon separators 5 mg/L, 1.5 to 50L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/11/4798-ce-steel-hydrocarbon-separators-5-mg-l-1-5-to-50l-s-v100-sludge-trap-main-image-800x565-optimized.jpeg)

![CE steel hydrocarbon separators 5 mg/L, 3 to 50L/s, with bypass, V100 sludge trap 12 [4799] CE steel hydrocarbon separators 5 mg/L, 3 to 50L/s, with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/11/4799-ce-steel-hydrocarbon-separators-5-mg-l-3-to-50l-s-with-bypass-v100-sludge-trap-main-image-800x565-optimized.jpeg)

![CE ACIER 5 mg/l hydrocarbon separators with V300 sludge trap and circular primers 13 [4808] CE ACIER 5 mg/l hydrocarbon separators with V300 sludge trap and circular primers - Main image](https://simop.com/wp-content/uploads/2024/11/4808-ce-acier-5-mg-l-hydrocarbon-separators-with-v300-sludge-trap-and-circular-primers-main-image-800x800-optimized.png)

![CE 5 mg/l hydrocarbon separators with V300 sludge trap without closure kit 14 [4809] CE 5 mg/l hydrocarbon separators with V300 sludge trap without closure kit - Main image](https://simop.com/wp-content/uploads/2024/11/4809-ce-5-mg-l-hydrocarbon-separators-with-v300-sludge-trap-without-closure-kit-main-image-800x800-optimized.png)

![CE steel hydrocarbon separators 5 mg/L, 3 to 15L/s, V100 sludge trap and lift compartment (without pump) 15 [4816] CE steel hydrocarbon separators 5 mg/L, 3 to 15L/s, V100 sludge trap and lift compartment (without pump) - Main image](https://simop.com/wp-content/uploads/2024/11/4816-ce-steel-hydrocarbon-separators-5-mg-l-3-to-15l-s-v100-sludge-trap-and-lift-compartment-without-pump-main-image-800x578-optimized.jpeg)

![Junction boxes or sleeves for ATEX hydro alarm cable 16 [4977] Junction boxes or sleeves for ATEX hydro alarm cable - Main image](https://simop.com/wp-content/uploads/2024/11/4977-junction-boxes-or-sleeves-for-atex-hydro-alarm-cable-main-image-optimized.jpeg)

![SLUDGE DETECTION ALARM 17 [4978] SLUDGE DETECTION ALARM - Main image](https://simop.com/wp-content/uploads/2024/11/4978-sludge-detection-alarm-main-image-optimized.jpeg)

![OVERFILL DETECTION ALARM 18 [4979] OVERFILL DETECTION ALARM - Main image](https://simop.com/wp-content/uploads/2024/11/4979-overfill-detection-alarm-main-image-optimized.jpeg)

![Accessories for steel separators 19 [4980] Accessories for steel separators - Main image](https://simop.com/wp-content/uploads/2024/11/4980-accessories-for-steel-separators-main-image-800x800-optimized.png)

![Solar-powered hydrocarbon level alarm 20 [4981] Solar-powered hydrocarbon level alarm - Main image](https://simop.com/wp-content/uploads/2024/11/4981-solar-powered-hydrocarbon-level-alarm-main-image-800x800-optimized.png)

![Hydrocarbon level alarm 21 [4982] Hydrocarbon level alarm - Main image](https://simop.com/wp-content/uploads/2024/11/4982-hydrocarbon-level-alarm-main-image-800x800-optimized.png)

![Hydrocarbon level alarm SE version 22 [4993] Hydrocarbon level alarm SE version - Main image](https://simop.com/wp-content/uploads/2024/11/4993-hydrocarbon-level-alarm-se-version-main-image-optimized.jpeg)

![CE polyethylene hydrocarbon separator 5mg/L, 6 to 10L/s, with V300 sludge trap 23 [6690] CE polyethylene hydrocarbon separator 5mg/L, 6 to 10L/s, with V300 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/11/6690-ce-polyethylene-hydrocarbon-separator-5mg-l-6-to-10l-s-with-v300-sludge-trap-main-image-800x800-optimized.png)