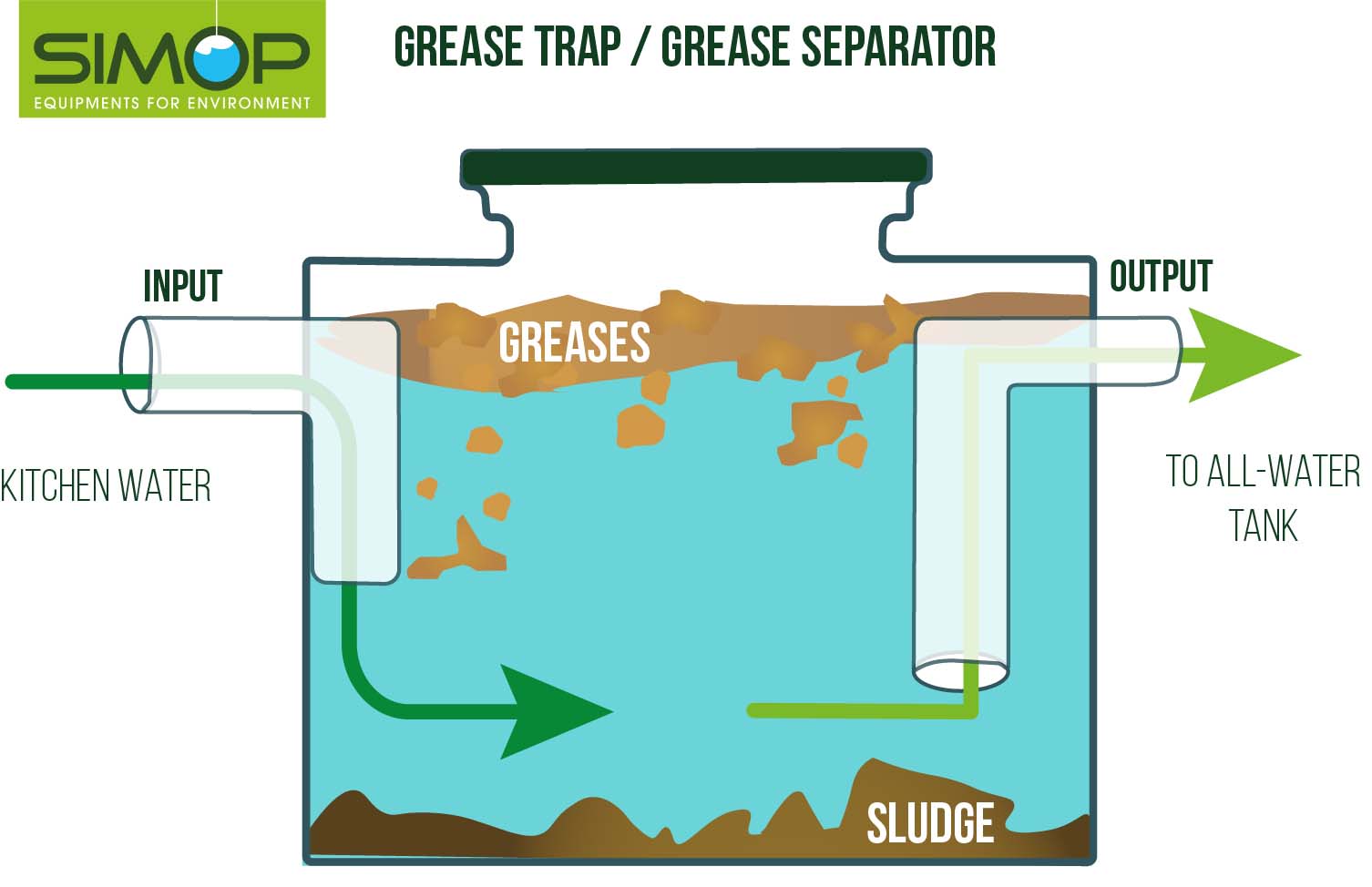

Grease trap operating principle

Efficient grease management is crucial for maintaining a clean and effective wastewater system

Grease separators are designed to treat water likely to be polluted by animal and/or vegetable fats before being discharged into the sewer system or the natural environment.

The component of a grease separator :

- Water inlet

- Sludge trap

- Partitioning (certain models only)

- Floating grease sheet

- Siphoid outlet

Many countries require the treatment of all types of waste, particularly bio-waste. Vegetable and animal oils and fats fall into the latter category, and must therefore be taken into account and treated. These fats need to be captured in a suitable system, which will then prevent clogging of the networks.

What’s more, most regional and even local regulations prohibit the discharge into wastewater of elements likely to harm the environment or public health. Catering professionals therefore equip themselves with treatment systems adapted to their activity.

Our solutions for grease treament

Our top products are designed to tackle grease and starch issues:

- Grease Traps: Capture and contain grease to prevent pipe blockages. Installing a grease trap ensures your plumbing stays clear and functional.

- Grease Separators: Efficiently separate grease from wastewater for smoother operations. A grease separator is essential for any commercial kitchen.

- Grease and Starch Separators: Dual-function units handle both grease and starch, ensuring thorough treatment. Invest in a grease and starch separator for comprehensive wastewater management.

- Starch Separators: Specialized in removing starch, keeping your system free from clogs. A starch separator works in tandem with grease traps for optimal performance.

- Accessories: Enhance the performance of all these products with our range of high-quality accessories for grease traps and grease separators.

Click now to discover the best solutions for your grease management needs!