Runoff water, as it travels over impermeable surfaces, becomes loaded with pollutants such as hydrocarbons and suspended solids. A hydrocarbon separator fitted with a sludge separator enables sites such as car washes, petrol stations and parking lots to treat and decontaminate their water. These sites are obliged to install a CE-compliant hydrocarbon separator.

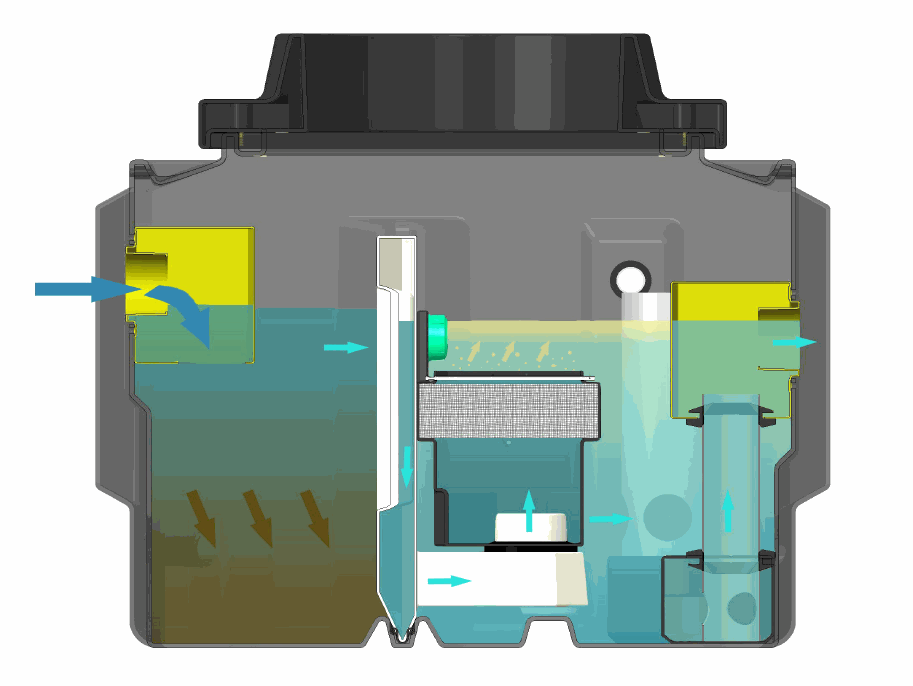

Water loaded with hydrocarbons and suspended solids arrives in the silt storage compartment, where the heavy suspended solids settle and form sludge, which must be cleaned regularly. Next, the water flows through a coalescing filter system that allows the hydrocarbon molecules to agglomerate and separate from the water (by density difference). The hydrocarbons thus form a layer on the surface of the separator compartment. This layer of hydrocarbons must be emptied more or less regularly, depending on the activity of the site to be treated.

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 sludge trap, top: circular primers 5 [4730] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 sludge trap, top: circular primers - Main image](https://simop.com/wp-content/uploads/2024/12/4730-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-v100-sludge-trap-top-circular-primers-main-image-800x800-optimized.png)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 silt storage, top: unenclosed 6 [4731] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 silt storage, top: unenclosed - Main image](https://simop.com/wp-content/uploads/2024/12/4731-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-v100-silt-storage-top-unenclosed-main-image-800x549-optimized.jpeg)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: circular primers 7 [4732] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: circular primers - Main image](https://simop.com/wp-content/uploads/2024/12/4732-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-with-bypass-v100-sludge-trap-top-circular-primers-main-image-800x800-optimized.png)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: without closure 8 [4733] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: without closure - Main image](https://simop.com/wp-content/uploads/2024/12/4733-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-with-bypass-v100-sludge-trap-top-without-closure-main-image-800x800-optimized.png)

![CE steel hydrocarbon separators 5 mg/L, 1.5 to 50L/s, V100 sludge trap 9 [4798] CE steel hydrocarbon separators 5 mg/L, 1.5 to 50L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/4798-ce-steel-hydrocarbon-separators-5-mg-l-1-5-to-50l-s-v100-sludge-trap-main-image-800x565-optimized.jpeg)

![CE steel hydrocarbon separators 5 mg/L, 3 to 50L/s, with bypass, V100 sludge trap 10 [4799] CE steel hydrocarbon separators 5 mg/L, 3 to 50L/s, with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/4799-ce-steel-hydrocarbon-separators-5-mg-l-3-to-50l-s-with-bypass-v100-sludge-trap-main-image-800x565-optimized.jpeg)

![CE ACIER 5 mg/l hydrocarbon separators with V300 sludge trap and circular primers 11 [4808] CE ACIER 5 mg/l hydrocarbon separators with V300 sludge trap and circular primers - Main image](https://simop.com/wp-content/uploads/2024/12/4808-ce-acier-5-mg-l-hydrocarbon-separators-with-v300-sludge-trap-and-circular-primers-main-image-800x800-optimized.png)

![CE 5 mg/l hydrocarbon separators with V300 sludge trap without closure kit 12 [4809] CE 5 mg/l hydrocarbon separators with V300 sludge trap without closure kit - Main image](https://simop.com/wp-content/uploads/2024/12/4809-ce-5-mg-l-hydrocarbon-separators-with-v300-sludge-trap-without-closure-kit-main-image-800x800-optimized.png)

![CE steel hydrocarbon separators 5 mg/L, 3 to 15L/s, V100 sludge trap and lift compartment (without pump) 13 [4816] CE steel hydrocarbon separators 5 mg/L, 3 to 15L/s, V100 sludge trap and lift compartment (without pump) - Main image](https://simop.com/wp-content/uploads/2024/12/4816-ce-steel-hydrocarbon-separators-5-mg-l-3-to-15l-s-v100-sludge-trap-and-lift-compartment-without-pump-main-image-800x578-optimized.jpeg)

![Junction boxes or sleeves for ATEX hydro alarm cable 14 [4977] Junction boxes or sleeves for ATEX hydro alarm cable - Main image](https://simop.com/wp-content/uploads/2024/12/4977-junction-boxes-or-sleeves-for-atex-hydro-alarm-cable-main-image-optimized.jpeg)

![SLUDGE DETECTION ALARM 15 [4978] SLUDGE DETECTION ALARM - Main image](https://simop.com/wp-content/uploads/2024/12/4978-sludge-detection-alarm-main-image-optimized.jpeg)

![OVERFILL DETECTION ALARM 16 [4979] OVERFILL DETECTION ALARM - Main image](https://simop.com/wp-content/uploads/2024/12/4979-overfill-detection-alarm-main-image-optimized.jpeg)

![Accessories for steel separators 17 [4980] Accessories for steel separators - Main image](https://simop.com/wp-content/uploads/2024/12/4980-accessories-for-steel-separators-main-image-800x800-optimized.png)

![Solar-powered hydrocarbon level alarm 18 [4981] Solar-powered hydrocarbon level alarm - Main image](https://simop.com/wp-content/uploads/2024/12/4981-solar-powered-hydrocarbon-level-alarm-main-image-800x800-optimized.png)

![Hydrocarbon level alarm 19 [4982] Hydrocarbon level alarm - Main image](https://simop.com/wp-content/uploads/2024/12/4982-hydrocarbon-level-alarm-main-image-800x800-optimized.png)

![ADJUSTABLE ENHANCER FOR OIL SEPARATORS 20 [6069] ADJUSTABLE ENHANCER FOR OIL SEPARATORS - Main image](https://simop.com/wp-content/uploads/2024/12/6069-adjustable-enhancer-for-oil-separators-main-image-800x800-optimized.png)

![Polyethylene sludge trap 21 [6603] Polyethylene sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6603-polyethylene-sludge-trap-main-image-800x992-optimized.png)

![GRP SLUDGE TRAPS 22 [6605] GRP SLUDGE TRAPS - Main image](https://simop.com/wp-content/uploads/2024/12/6605-grp-sludge-traps-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 1.5 to 15L/s, V100 sludge trap 23 [6645] CE polyethylene hydrocarbon separator 5mg/L, 1.5 to 15L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6645-ce-polyethylene-hydrocarbon-separator-5mg-l-1-5-to-15l-s-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, V100 sludge trap 24 [6647] CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6647-ce-polyethylene-hydrocarbon-separator-5mg-l-20-to-30l-s-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, with bypass, V100 sludge trap 25 [6648] CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6648-ce-polyethylene-hydrocarbon-separator-5mg-l-20-to-30l-s-with-bypass-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5 mg/L, 3 to 15 L/s , with bypass, V100 sludge trap 26 [6649] CE polyethylene hydrocarbon separator 5 mg/L, 3 to 15 L/s , with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6649-ce-polyethylene-hydrocarbon-separator-5-mg-l-3-to-15-l-s-with-bypass-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyester 5mg/L hydrocarbon separator, 35 to 200 L/s, V100 sludge trap 27 [6658] CE polyester 5mg/L hydrocarbon separator, 35 to 200 L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6658-ce-polyester-5mg-l-hydrocarbon-separator-35-to-200-l-s-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyester 5mg/L hydrocarbon separator, 35 to 50 L/s, with bypass 28 [6659] CE polyester 5mg/L hydrocarbon separator, 35 to 50 L/s, with bypass - Main image](https://simop.com/wp-content/uploads/2024/12/6659-ce-polyester-5mg-l-hydrocarbon-separator-35-to-50-l-s-with-bypass-main-image-800x800-optimized.png)

![CE polyester hydrocarbon separator, flow rate over 50 L/s, made to measure 29 [6668] CE polyester hydrocarbon separator, flow rate over 50 L/s, made to measure - Main image](https://simop.com/wp-content/uploads/2024/12/6668-ce-polyester-hydrocarbon-separator-flow-rate-over-50-l-s-made-to-measure-main-image-800x800-optimized.png)

![CE polyester hydrocarbon separator, flow rate greater than 50 L/s, with by-pass, custom-made 30 [6669] CE polyester hydrocarbon separator, flow rate greater than 50 L/s, with by-pass, custom-made - Main image](https://simop.com/wp-content/uploads/2024/12/6669-ce-polyester-hydrocarbon-separator-flow-rate-greater-than-50-l-s-with-by-pass-custom-made-main-image-800x800-optimized.png)

![Fario2 PRV hydro separator with downstream bypass 31 [6670] Fario2 PRV hydro separator with downstream bypass - Main image](https://simop.com/wp-content/uploads/2024/12/6670-fario2-prv-hydro-separator-with-downstream-bypass-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 6 to 10L/s, with V300 sludge trap 32 [6690] CE polyethylene hydrocarbon separator 5mg/L, 6 to 10L/s, with V300 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6690-ce-polyethylene-hydrocarbon-separator-5mg-l-6-to-10l-s-with-v300-sludge-trap-main-image-800x800-optimized.png)