Treating run-off water in the industrial sector is essential to prevent environmental pollution and protect aquatic ecosystems. Industries such as chemicals, pharmaceuticals, food processing and plastics generate a wide range of pollutants. If not properly treated, these pollutants can have harmful consequences on surface and groundwater quality, public health and biodiversity.

The importance of treating industrial runoff

Runoff from industrial sites often contains a wide range of contaminants, specific to each sector:

- Chemical industry: Toxic chemicals, solvents, hydrocarbons, heavy metals and manufacturing process residues are frequently found.

- Pharmaceutical industry: Runoff can contain traces of drugs, volatile organic compounds and active substances.

- Plastics industry: Microplastics, resins and other polymers are common pollutants.

- Food industry: Water can be laden with organic matter, fats, oils and cleaning products, as well as plastics used for packaging.

- Metal industry: the main pollutants are heavy metals such as cadmium, zinc and copper, cutting oils and acids and alkalis.

- Textile industry: releases dyes, treatment chemicals such as formaldehyde and microfibers.

- Paper industry: uses chlorine-based bleaching chemicals, resins and produces suspended solids.

Hydrocarbon Separators: An Essential Solution

What is an Oil Separator?

An hydrocarbon separator is a device designed to remove hydrocarbons from run-off water. It is particularly relevant for industries where oils, fuels and other petroleum products are present, such as garages, service stations, industrial sites and parking lots.

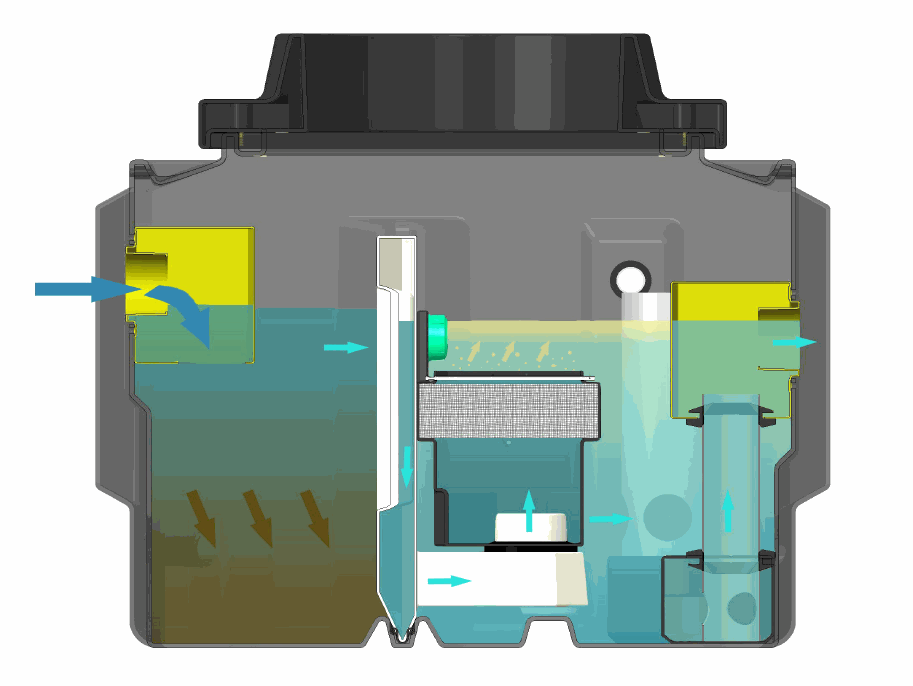

The hydrocarbon separator uses the difference in density between water and hydrocarbons to separate the two substances. The heavier water flows downwards, while the lighter hydrocarbons rise to the surface. The system is generally equipped with several compartments and filters to ensure effective separation and prevent the dispersion of hydrocarbons.

Obligations and standards

Regulations often require the installation of oil separators for industries handling petroleum products. It’s crucial to check local standards and requirements specific to your sector to ensure compliance. For example, separators often need to be certified to standards such as EN 858.

Trithon Hydrodynamic Separator: Advanced Technology

What is a Trithon Hydrodynamic Separator?

The Trithon Hydrodynamic Separator is an innovative solution for stormwater treatment. It combines natural settling and centrifugal force to effectively trap pollutants. Trithon features include :

- Centrifugal settling: Heavy particles are pressed against the system walls and directed into the sludge storage compartment.

- Float separation: Light liquids and solids with densities below 0.93 are separated and retained.

- Overflow management: Capable of handling flows of up to 125% of the nominal flow rate, it enables peak flows to be managed without compromising treatment quality.

- Simplified maintenance: A technical platform provides easy access for inspection and emptying operations.

The installation of run-off water treatment systems, such as Trithon hydrocarbon separators and hydrodynamic separators, is an obligation for many industries. This equipment helps to comply with environmental regulations, protect water resources and ensure the safe, efficient operation of your facilities.

Find below the SIMOP range of equipments for industries :

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 sludge trap, top: circular primers 8 [4730] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 sludge trap, top: circular primers - Main image](https://simop.com/wp-content/uploads/2024/12/4730-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-v100-sludge-trap-top-circular-primers-main-image-800x800-optimized.png)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 silt storage, top: unenclosed 9 [4731] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, V100 silt storage, top: unenclosed - Main image](https://simop.com/wp-content/uploads/2024/12/4731-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-v100-silt-storage-top-unenclosed-main-image-800x549-optimized.jpeg)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: circular primers 10 [4732] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: circular primers - Main image](https://simop.com/wp-content/uploads/2024/12/4732-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-with-bypass-v100-sludge-trap-top-circular-primers-main-image-800x800-optimized.png)

![CE steel hydrocarbon separators 5 mg/L, 1.5 to 50L/s, V100 sludge trap 11 [4798] CE steel hydrocarbon separators 5 mg/L, 1.5 to 50L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/4798-ce-steel-hydrocarbon-separators-5-mg-l-1-5-to-50l-s-v100-sludge-trap-main-image-800x565-optimized.jpeg)

![CE steel hydrocarbon separators 5 mg/L, 3 to 50L/s, with bypass, V100 sludge trap 12 [4799] CE steel hydrocarbon separators 5 mg/L, 3 to 50L/s, with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/4799-ce-steel-hydrocarbon-separators-5-mg-l-3-to-50l-s-with-bypass-v100-sludge-trap-main-image-800x565-optimized.jpeg)

![CE 5 mg/l hydrocarbon separators with V300 sludge trap without closure kit 13 [4809] CE 5 mg/l hydrocarbon separators with V300 sludge trap without closure kit - Main image](https://simop.com/wp-content/uploads/2024/12/4809-ce-5-mg-l-hydrocarbon-separators-with-v300-sludge-trap-without-closure-kit-main-image-800x800-optimized.png)

![CE ACIER 5 mg/l hydrocarbon separators with V300 sludge trap and circular primers 14 [4808] CE ACIER 5 mg/l hydrocarbon separators with V300 sludge trap and circular primers - Main image](https://simop.com/wp-content/uploads/2024/12/4808-ce-acier-5-mg-l-hydrocarbon-separators-with-v300-sludge-trap-and-circular-primers-main-image-800x800-optimized.png)

![Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: without closure 15 [4733] Hydrocarbon separator NF steel 5mg/L, 1.5 to 6 L/s, with bypass, V100 sludge trap, top: without closure - Main image](https://simop.com/wp-content/uploads/2024/12/4733-hydrocarbon-separator-nf-steel-5mg-l-1-5-to-6-l-s-with-bypass-v100-sludge-trap-top-without-closure-main-image-800x800-optimized.png)

![CE steel hydrocarbon separators 5 mg/L, 3 to 15L/s, V100 sludge trap and lift compartment (without pump) 16 [4816] CE steel hydrocarbon separators 5 mg/L, 3 to 15L/s, V100 sludge trap and lift compartment (without pump) - Main image](https://simop.com/wp-content/uploads/2024/12/4816-ce-steel-hydrocarbon-separators-5-mg-l-3-to-15l-s-v100-sludge-trap-and-lift-compartment-without-pump-main-image-800x578-optimized.jpeg)

![TRITHON Polyethylene hydrodynamic separator 17 [6500] TRITHON Polyethylene hydrodynamic separator - Main image](https://simop.com/wp-content/uploads/2024/12/6500-trithon-polyethylene-hydrodynamic-separator-main-image-800x1129-optimized.jpeg)

![Junction boxes or sleeves for ATEX hydro alarm cable 18 [4977] Junction boxes or sleeves for ATEX hydro alarm cable - Main image](https://simop.com/wp-content/uploads/2024/12/4977-junction-boxes-or-sleeves-for-atex-hydro-alarm-cable-main-image-optimized.jpeg)

![SLUDGE DETECTION ALARM 19 [4978] SLUDGE DETECTION ALARM - Main image](https://simop.com/wp-content/uploads/2024/12/4978-sludge-detection-alarm-main-image-optimized.jpeg)

![OVERFILL DETECTION ALARM 20 [4979] OVERFILL DETECTION ALARM - Main image](https://simop.com/wp-content/uploads/2024/12/4979-overfill-detection-alarm-main-image-optimized.jpeg)

![Accessories for steel separators 21 [4980] Accessories for steel separators - Main image](https://simop.com/wp-content/uploads/2024/12/4980-accessories-for-steel-separators-main-image-800x800-optimized.png)

![Solar-powered hydrocarbon level alarm 22 [4981] Solar-powered hydrocarbon level alarm - Main image](https://simop.com/wp-content/uploads/2024/12/4981-solar-powered-hydrocarbon-level-alarm-main-image-800x800-optimized.png)

![Hydrocarbon level alarm 23 [4982] Hydrocarbon level alarm - Main image](https://simop.com/wp-content/uploads/2024/12/4982-hydrocarbon-level-alarm-main-image-800x800-optimized.png)

![Hydrocarbon level alarm SE version 24 [4993] Hydrocarbon level alarm SE version - Main image](https://simop.com/wp-content/uploads/2024/12/4993-hydrocarbon-level-alarm-se-version-main-image-optimized.jpeg)

![CE polyethylene hydrocarbon separator 5mg/L, 1.5 to 15L/s, V100 sludge trap 25 [6645] CE polyethylene hydrocarbon separator 5mg/L, 1.5 to 15L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6645-ce-polyethylene-hydrocarbon-separator-5mg-l-1-5-to-15l-s-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, V100 sludge trap 26 [6647] CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6647-ce-polyethylene-hydrocarbon-separator-5mg-l-20-to-30l-s-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, with bypass, V100 sludge trap 27 [6648] CE polyethylene hydrocarbon separator 5mg/L, 20 to 30L/s, with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6648-ce-polyethylene-hydrocarbon-separator-5mg-l-20-to-30l-s-with-bypass-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5 mg/L, 3 to 15 L/s , with bypass, V100 sludge trap 28 [6649] CE polyethylene hydrocarbon separator 5 mg/L, 3 to 15 L/s , with bypass, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6649-ce-polyethylene-hydrocarbon-separator-5-mg-l-3-to-15-l-s-with-bypass-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyester 5mg/L hydrocarbon separator, 35 to 200 L/s, V100 sludge trap 29 [6658] CE polyester 5mg/L hydrocarbon separator, 35 to 200 L/s, V100 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6658-ce-polyester-5mg-l-hydrocarbon-separator-35-to-200-l-s-v100-sludge-trap-main-image-800x800-optimized.png)

![CE polyester 5mg/L hydrocarbon separator, 35 to 50 L/s, with bypass 30 [6659] CE polyester 5mg/L hydrocarbon separator, 35 to 50 L/s, with bypass - Main image](https://simop.com/wp-content/uploads/2024/12/6659-ce-polyester-5mg-l-hydrocarbon-separator-35-to-50-l-s-with-bypass-main-image-800x800-optimized.png)

![CE polyester hydrocarbon separator, flow rate over 50 L/s, made to measure 31 [6668] CE polyester hydrocarbon separator, flow rate over 50 L/s, made to measure - Main image](https://simop.com/wp-content/uploads/2024/12/6668-ce-polyester-hydrocarbon-separator-flow-rate-over-50-l-s-made-to-measure-main-image-800x800-optimized.png)

![CE polyester hydrocarbon separator, flow rate greater than 50 L/s, with by-pass, custom-made 32 [6669] CE polyester hydrocarbon separator, flow rate greater than 50 L/s, with by-pass, custom-made - Main image](https://simop.com/wp-content/uploads/2024/12/6669-ce-polyester-hydrocarbon-separator-flow-rate-greater-than-50-l-s-with-by-pass-custom-made-main-image-800x800-optimized.png)

![Fario2 PRV hydro separator with downstream bypass 33 [6670] Fario2 PRV hydro separator with downstream bypass - Main image](https://simop.com/wp-content/uploads/2024/12/6670-fario2-prv-hydro-separator-with-downstream-bypass-main-image-800x800-optimized.png)

![CE polyethylene hydrocarbon separator 5mg/L, 6 to 10L/s, with V300 sludge trap 34 [6690] CE polyethylene hydrocarbon separator 5mg/L, 6 to 10L/s, with V300 sludge trap - Main image](https://simop.com/wp-content/uploads/2024/12/6690-ce-polyethylene-hydrocarbon-separator-5mg-l-6-to-10l-s-with-v300-sludge-trap-main-image-800x800-optimized.png)